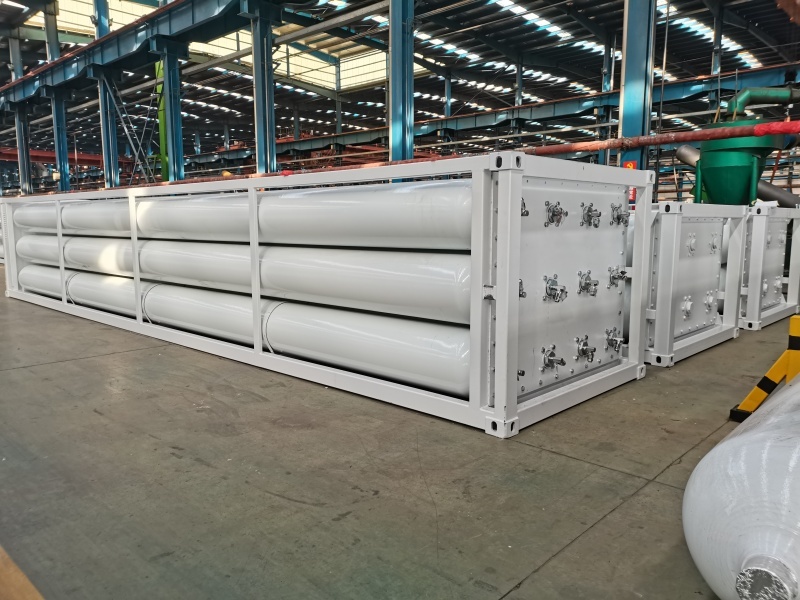

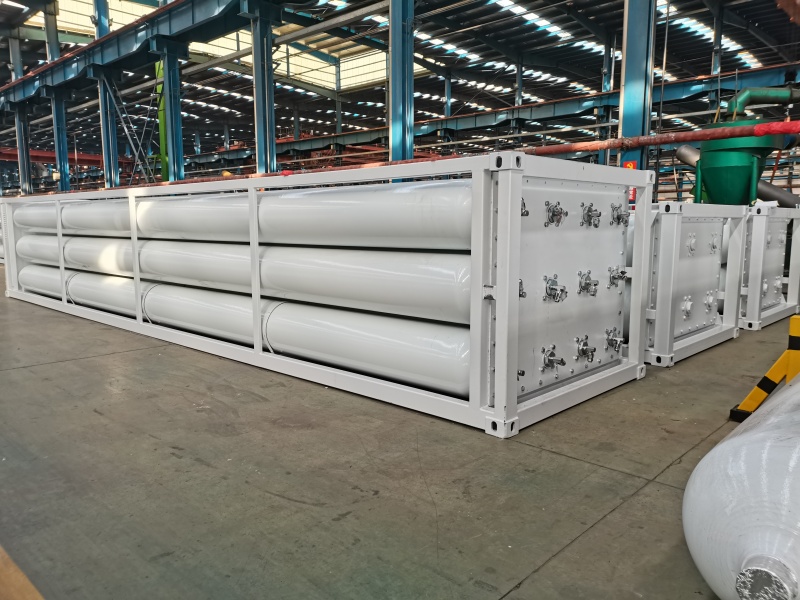

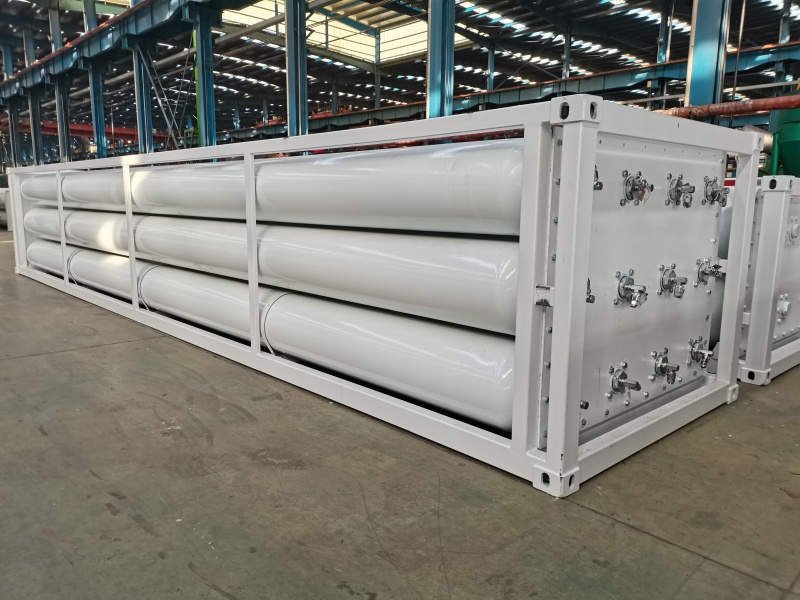

Tube skid container

H2 tube skid container can store and transport hydrogen; they are designed, manufactured, inspected and accepted according to:

ISO11120 Cylinder-design, structure and test of seamless and reusable steel tube with a capacity between 150 L to 3000 L.

Series 1: ISO 668 Classification, dimensions and ratings of container

Application:

1. For H2 transportation from Mother station/ gas reserve to daughter station;

2. For H2 transportation to places where pipeline network hasn’t been built;

3. For H2 transportation to places where can’t reach existing distribution system etc;

4. For H2 storage at gas stations.

Specification of H2 container

|

11-tubes H2 tube skid container ( 40ft ) Execution standard : ISO11120 Cylinder-design , structure and test of seamless and reusable steel tube with a capacity between 150 L to3000 L .ISO 668 Classification , dimensions and ratings of series 1 container |

|||||

|

Tube Bundle Container |

Item |

Data |

Cylinder |

Item |

Data |

|

Type |

GSJ11-2210- H2 -25 |

Working pressure |

25MPa |

||

|

Container quality |

34259 Kg |

Working temperature |

-50~65℃ |

||

|

Filling quality |

419.7Kg |

Main material |

4130X |

||

|

Rated weight |

34750.7Kg |

cylinder QTY |

11 |

||

|

Major risk category |

2.1 |

Total volume |

24.31M3 |

||

|

UN code |

1049 |

Pressure for water pressure test |

37.5MPa |

||

|

Filling medium |

H2 |

Dimension(Φx Wall Thickness x Length) |

559x18.4x10975 mm |

||

|

Gas tightness test pressure |

25MPa |

Design temperature |

65℃ |

||

|

Pipeline water pressure test pressure |

37.5MPa |

Medium property |

Explosive |

||

|

Filling amount |

5469.75Nm3 |

Bursting discs |

Burst pressure |

37.5MPa |

|

|

Dimension (LxWxH) |

12192x2438x1900 mm |

||||

|

Transporting |

Highway combined transport |

Bursting disc device discharge aperture |

≥20 |

||

|

Design service life |

Fifteen years |

||||

Qingdao Sino Energy Tech Co.,Ltd

Qingdao Sino Energy Tech Co.,Ltd